About Us

Rekpa Installation Materials San. Trade A.Ş. was established in 1994 and continues its activities in the fields of manufacturing, import and export of installation materials. Our company, which specializes in separation (separator), is Turkey's leading manufacturer. It has strengthened its quality in production with CE and TSEK certificates. Our production, which is sent to many countries of the world, is the proof of our production quality. We offer our productions and other products to your service in order to increase the efficiency of your installation and to provide ease of maintenance, repair and control.

About UsSeparators

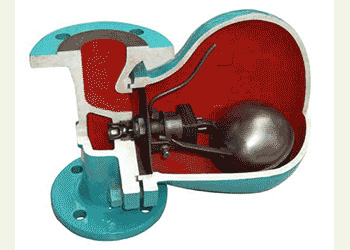

Vortex Separators

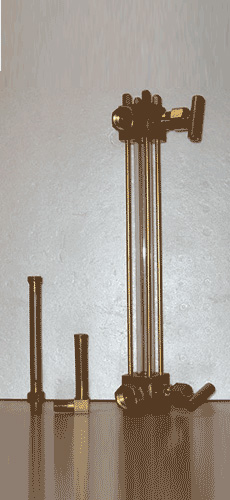

It is not possible for liquid droplets to disperse regularly over the entire pipe section. It is easy to get the liquid flowing from the bottom of the pipe. Free-floating ones can only be collected with separators. When the free gas filled with moisture of variable size enters the separator, it starts centrifugal movement around the conical cyclone or fin downwards, and separates the liquid particles, droplets and sediments in the gas with increasing velocity by being thrown towards the wall. The dry and clean gas descending into the large internal volume is directed to the collector conical cyclone, (optionally passing through the filter) and continues on its way in the installation. Liquid and sediments go down to the collection chamber under the separator stainless plate and cannot go up again. The liquid can be evacuated automatically with a trap by passing through the filter, or it can be evacuated manually. The level of the liquid accumulated in the collection chamber can be controlled by the control pipe.

It is not possible for liquid droplets to disperse regularly over the entire pipe section. It is easy to get the liquid flowing from the bottom of the pipe. Free-floating ones can only be collected with separators. When the free gas filled with moisture of variable size enters the separator, it starts centrifugal movement around the conical cyclone or fin downwards, and separates the liquid particles, droplets and sediments in the gas with increasing velocity by being thrown towards the wall. The dry and clean gas descending into the large internal volume is directed to the collector conical cyclone, (optionally passing through the filter) and continues on its way in the installation. Liquid and sediments go down to the collection chamber under the separator stainless plate and cannot go up again. The liquid can be evacuated automatically with a trap by passing through the filter, or it can be evacuated manually. The level of the liquid accumulated in the collection chamber can be controlled by the control pipe.

BOILER OUTLETS: It prevents the chemicals, corrosive liquids, foreign substances and water droplets in the feed water from being transported to the steam lines.

INTO CONTROL DEVICES: Increases the efficiency of equipment such as pressure reducers, control valves, steam meters, and extends their life.

To SYSTEM INLETS: It prevents turbine blades and body wear by separating water particles at the inlet of steam turbines.

Heating coils and dryers. • Kitchen appliances, laundry machines.

Multi-layer presses (Rubber and wood presses)

Autoclaves, sterilizers

Dyeing and finishing machines.

Bread ovens.

In tea and tobacco businesses.

It reduces operating cost. Takes shock loads on working equipment Prevents equipment damage due to erosion and corrosion No electrical energy is needed. Maintenance free. It is affordable.

REKPA

Catalogs

Factory Catalog